Raw bioTAL (left) can be combined with other chemicals and processed into a biorenewable, recyclable PDK plastic (right). (Credit: Jeremy Demarteau/Berkeley Lab)

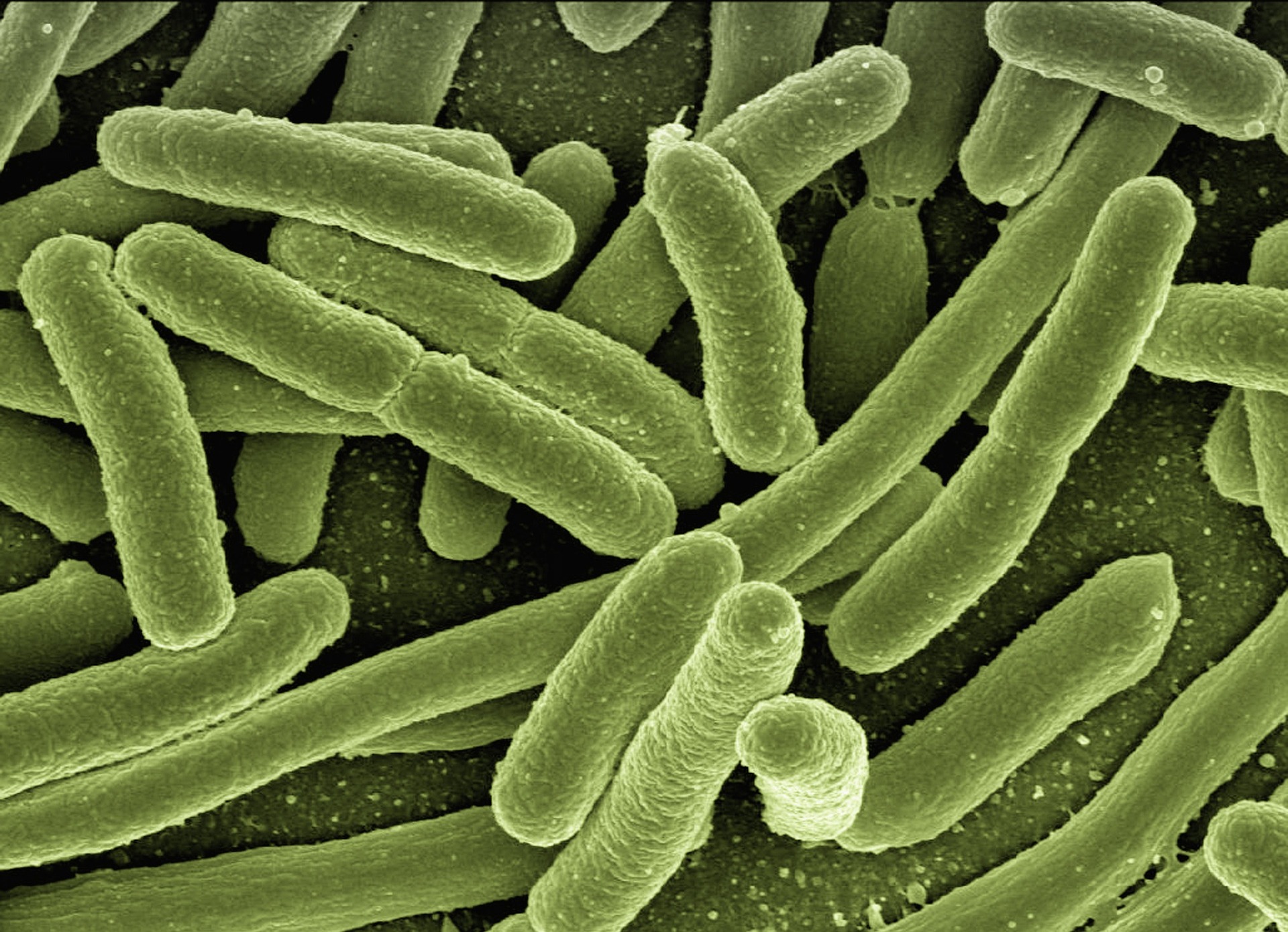

Scientists at the Lawrence Berkeley National Laboratory in Berkeley, California successfully engineered microbes to make biological alternatives for the starting ingredients in an infinitely recyclable plastic known as poly diketoenamine, or PDK. The new approach shows that renewable, recyclable plastics are not only possible, but also outperform those from petrochemicals. Unlike traditional plastics, PDK can be repeatedly deconstructed into pristine building blocks and formed into new products with no loss in quality, the Lab explains on their website. PDKs initially used building blocks derived from petrochemicals, but those ingredients can be redesigned and produced with microbes instead. The team managed to manipulate the bacterium E. coli in a way that it turns sugars from plants into some of the starting materials – a molecule known as triacetic acid lactone, or bioTAL – and produced a PDK with roughly 80% bio-content. “Our new results are extremely encouraging,” said Corinne Scown, a staff scientist in Berkeley Lab’s Energy Technologies Area and a vice president at JBEI. “We found that with even modest improvements to the production process, we could soon be making bio-based PDK plastics that are both cheaper and emit less CO2 than those made with fossil fuels.”