The Shellworks has developed a range of customized environmentally friendly packaging applications. Their work scope includes the entire process from extraction of the raw material to the final production. According to their Video it all starts with chitosan, the world’s 2nd most abundant biopolymer, which they extract from seafood waste.

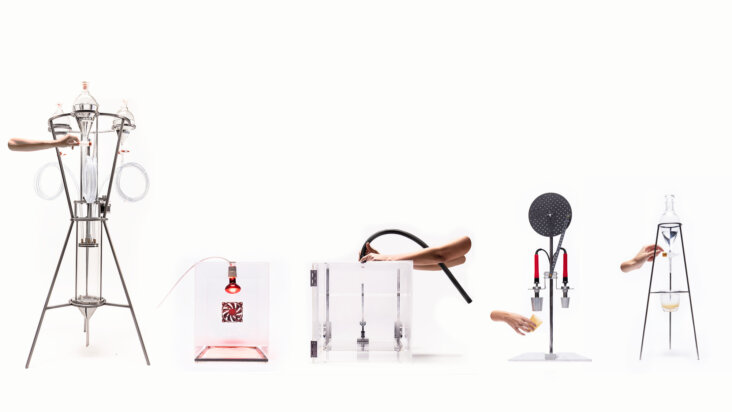

After reducing chitosan and vinegar to a pulp, the material is ready for being used as feed stock of various production processes, as for which they have seemingly developed their own manufacturing equipment, such as the evaporative sheet former “Sheety”; the hydro-thermal vacuum former “Vaccy”; a heated dip-moulder “Dippy” or “Drippy”, a hydro-recycler. The material, by the way, is infinitely recyclable and can be used as fertiliser if there is no use for it anymore.

Turning waste lobster shells into bioplastic - The Shellworks